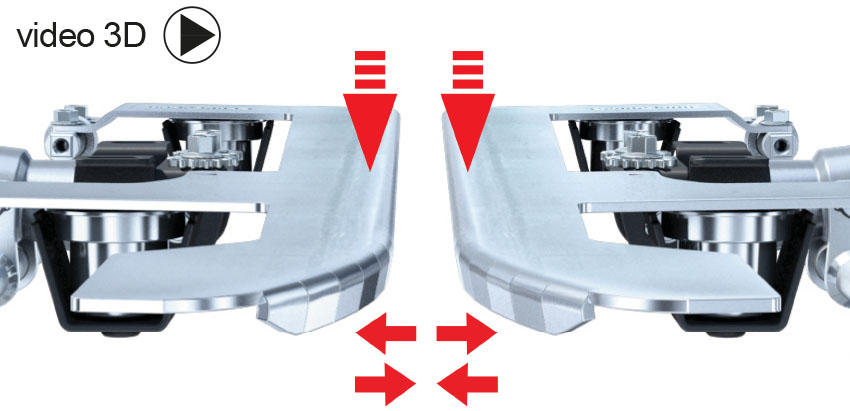

AUTOMATIC SELF-ADJUSTING SUSPENSION DECK PLATES

Total harvesting without losses of kernels and ears

Suspension deck plates: deck plates of the DragoGT corn head are equipped with a special suspension device able to absorb the impact of ears on the same plates: ears separate gentler, avoiding losing kernels and ears do not bounce out.

Automatic self-adjusting deck plates: in normal corn heads, deck plates opening is manually regulated, an inaccurate system that results in the loss of much product. Instead, the deck plates opening of DragoGT is automatic and continuously adapts to the different sizes of the corn stalks.

The automatism works independently on each row. The operator does not have to make any adjustment. Total harvesting, without losses.

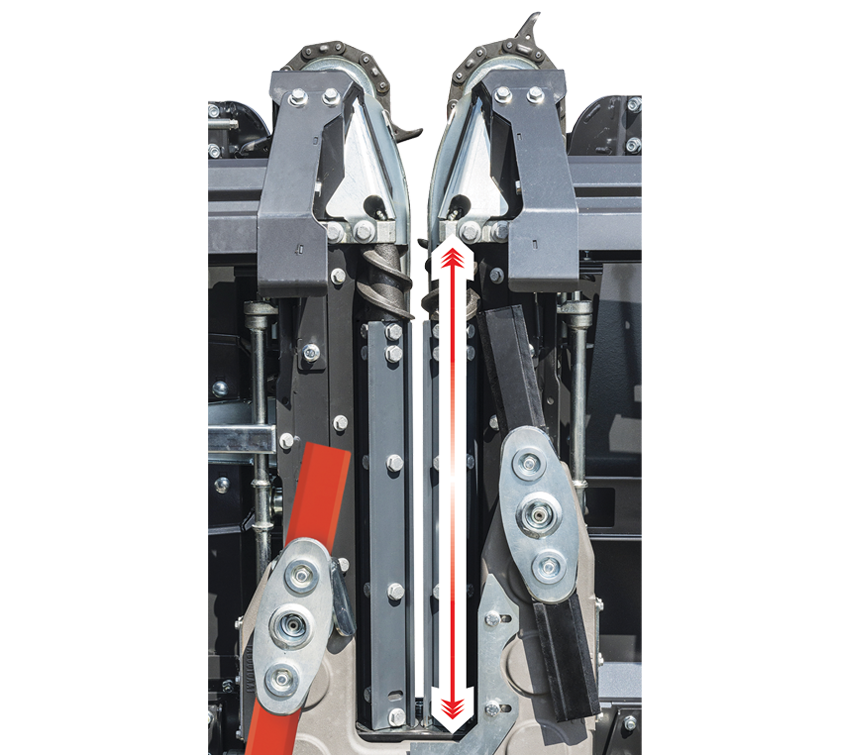

LONGER STALK ROLLERS

Perfectly pressed stalk

ADVANTAGES: gentle separation of the ear, avoiding kernel losses.

Stalk rollers are longer compared to normal corn heads: a lower peripheral rotation speed allows for a gentler separation of the ear from the plant. Stalk perfectly pressed, total harvesting, without losses.

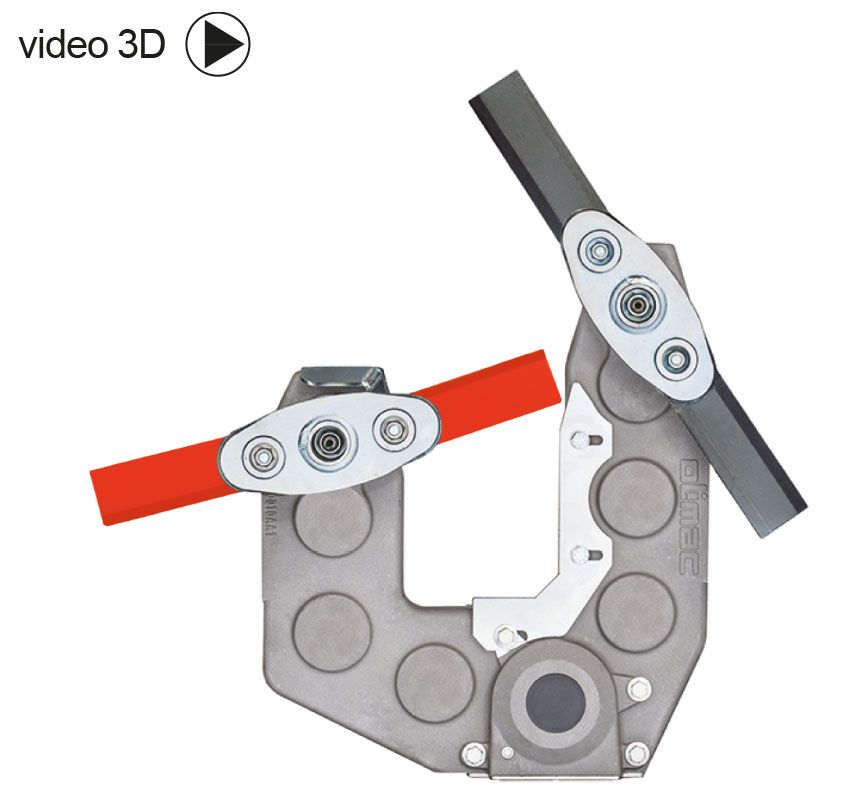

DOUBLE STALK CHOPPER SCISSOR EFFECT

Much finer chopping

Unique in the world, DragoGT is equipped with Double Stalk Chopper Scissor Effect: on each row there are four blades working, two on one side, two on the opposite, but with inverted rotation, like a scissors. Stalks are doubly shuttered and result shorter. Chopping operation is much finer compared to the one of all the other stalk choppers. Product on the ground decomposes much rapidly.

Double Stalk Chopper has low power consumption, equal to a single stalk chopper.

Single Stalk Chopper.

DragoGT is also available in the single stalk chopper version.

WATCH THE COMPARISON AMONG DRAGO GT AND THE OTHER CORN HEADS ACTUALLY ON THE MARKET

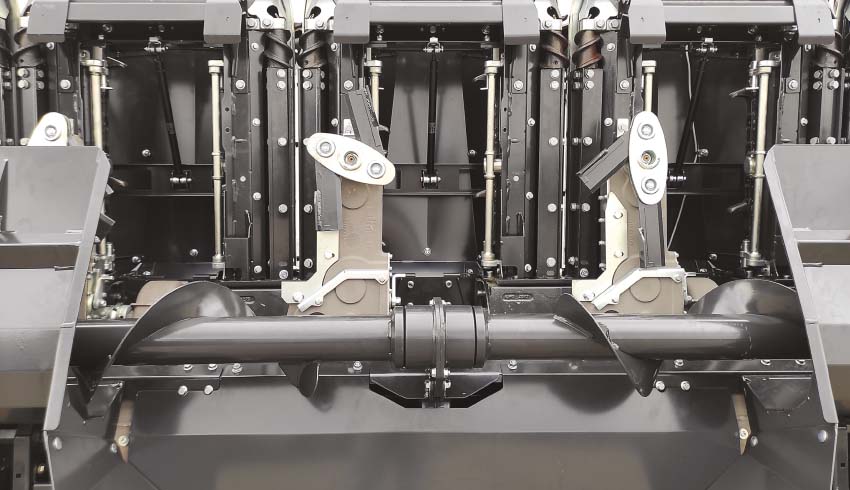

HYPER-DIMENSIONED AUGER

Higher forward speed in down corn, no obstructions

ADVANTAGES: obstructions and kernel losses avoided.

DragoGT is equipped with a new hyper-dimensioned auger of Ø 500 mm (the biggest in the sector) allowing higher forward speed in down and dry corn: so to avoid all obstructions and loss of kernels. Your combine-harvester will work at the highest performance level. Lateral augers and low profile construction allow for total harvesting even when ears are very low-lying or hanging.

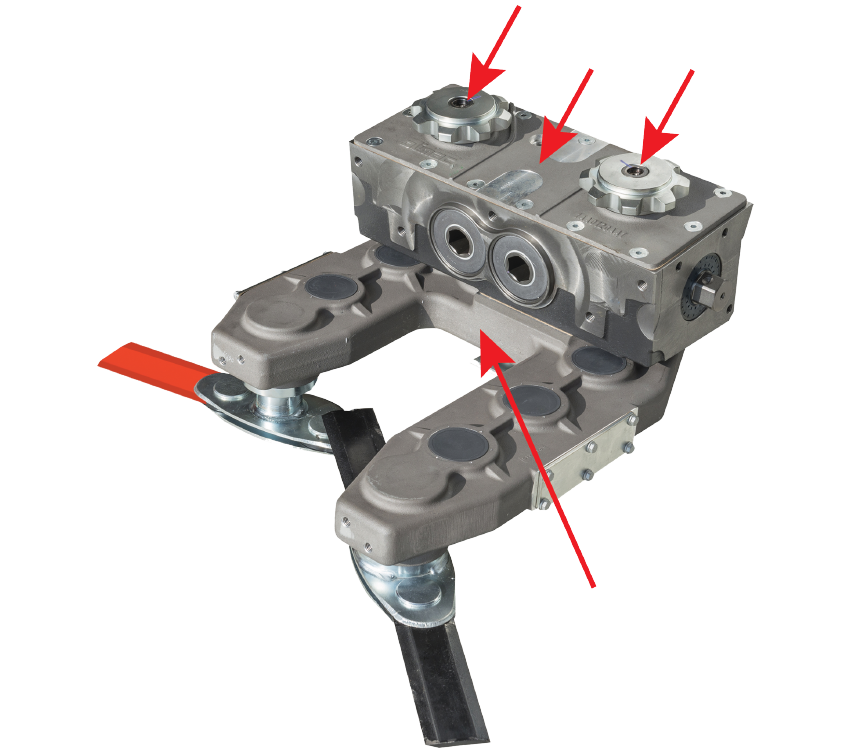

FOUR CLUTCHES FOR EACH ROW

Higher performance and safety

ADVANTAGES: higher safety and performance.

Normal corn heads have got only one clutch that intervenes in different movements. DragoGT, on the contrary, has got four clutches for each row. These four clutches have different calibrations, each one perfectly adequate for a specific movement: higher performance and safety.

SPIRAL BEVEL GEAR PAIRS

More power, less noise

ADVANTAGES: total power transmission, higher productivity.

Unique in the world in this sector, DragoGT is equipped with spiral bevel gear pairs of automotive origin, allowing for a total power transmission and guaranteeing a noiseless performance compared to traditional gears used by all other brands of corn heads.

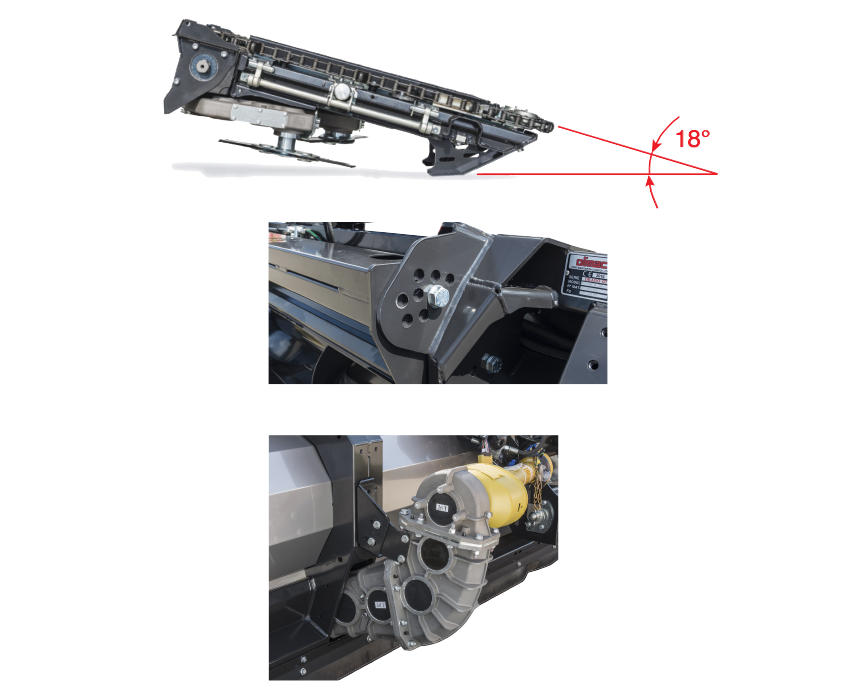

A WORLDWIDE UNIQUE TECHNOLOGY

More efficient in extreme working conditions

Working angle of 18°

Working angle of 18°

It allows the best harvesting of down corn, avoiding ears from bouncing out of the machine.

Adjustable connections

Adjustable connections

DragoGT can maintain its working position of 18° with any type and brand of combine-harvester, the most performing for a complete harvesting without losses. Adjustable connections allows maintaining this working position regardless the height of the wheels of the combine-harvester.

Gear box in light alloy

Gear box in light alloy

Olimac, thanks to its exclusive technology, has developed gear boxes in light alloy – this way the weight of the machine is reduced while its robustness is increased. All this by using cast iron when necessary. An extraordinary result only DragoGT can offer.

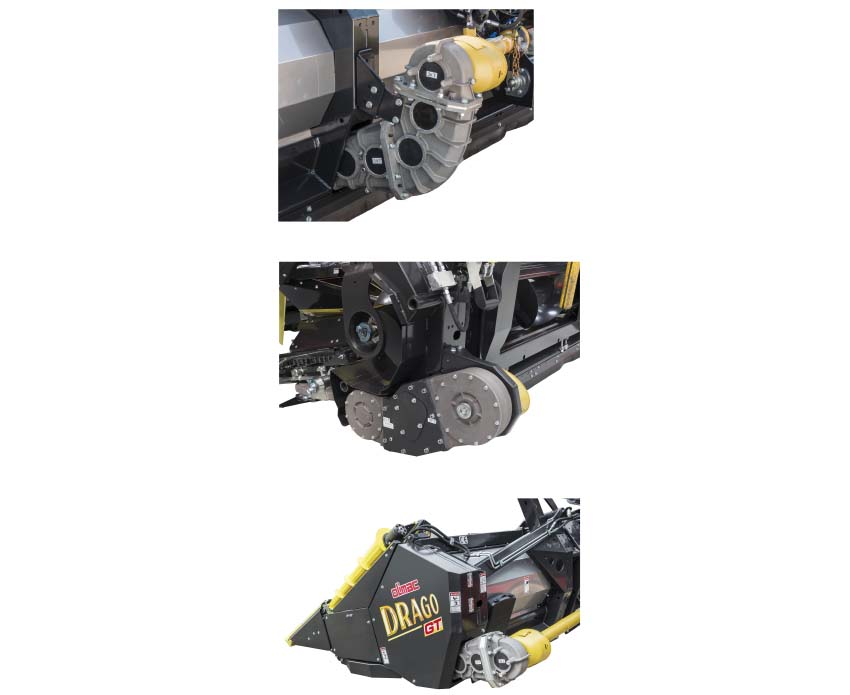

THREE TYPES OF TRANSMISSIONS

Super-performing, zero maintenance

Internal transmission with cylindrical gears for high powers

Internal transmission with cylindrical gears for high powers

DragoGT 6-8-10-12-16-18-24 fixed rows

DragoGT 9-10-12-16-18 foldable rows

High-performing transmission.

Zero maintenance, re-lubrication not required.

Total protection from impurities and foreign objects.

Oil-bathed internal transmission

DragoGT 6-8 foldable rows

High-performing transmission.

Zero maintenance, re-lubrication not required.

Total protection from impurities and foreign objects.

External transmission with cylindrical gears

External transmission with cylindrical gears

DragoGT 6-8 foldable rows

High-performing transmission.

Zero maintenance, re-lubrication not required.

Total protection from impurities and foreign objects. Ideal for hill areas.

THREE-TIME LONG LASTING

Corn head lasts more, excellent aesthetics

Olimac plant, that is totally automatic and robotic, ensures a lifetime of the painting which is three times higher than the average of the sector: excellent aesthetics and longer life of the corn head are guaranteed.

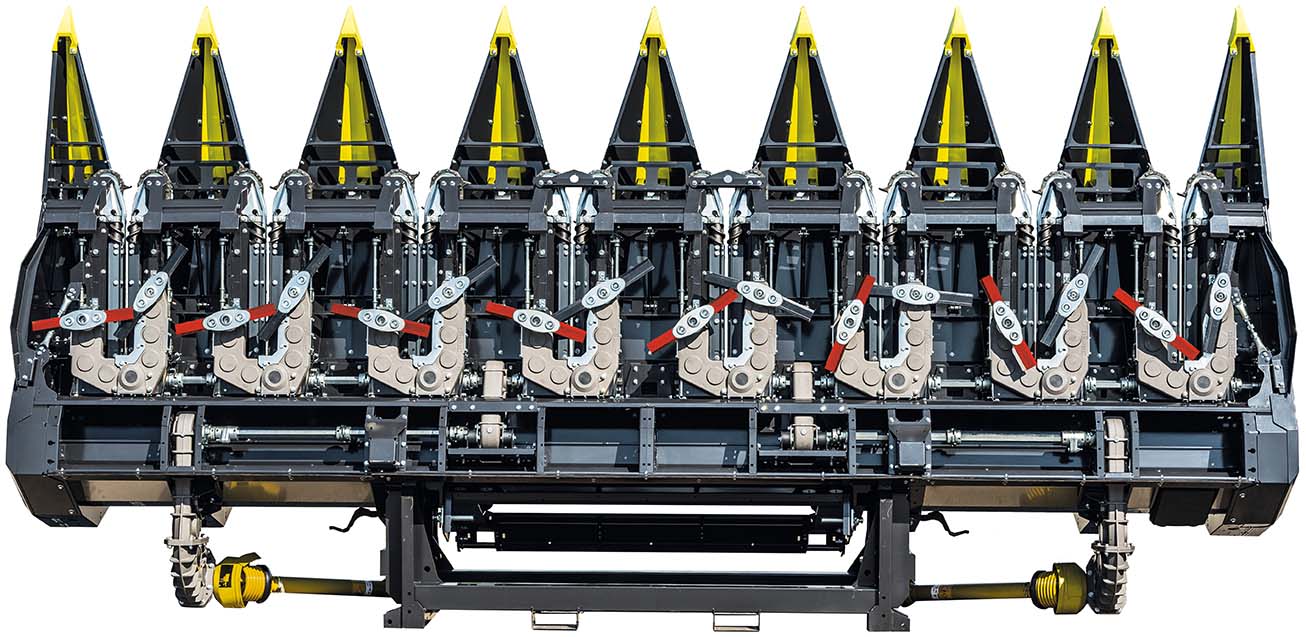

DRAGO GT: 4 TO 24 ROWS, FIXED OR FOLDABLE

Customized according to your needs

A team of technicians develops and fine-tunes

special configurations to satisfy requests from each customer.

Support and original spare parts

A worldwide network of Olimac Autorized Centers, assures competent support and rapid response to solve any problem. The use of original Olimac spare parts will guarantee safe operations and long life for your DragoGT corn head.

Foldable from the driving seat – DragoGT can be foldable right from the driving seat. Reduced encumbrance together with total visibility make it easier to drive on the road.

DragoGT 24 rows, the giant of corn!

DRAGO GT ACCESSORIES

Auger for collecting corn residues.

More agricultural income and sustainable development.

With the same pass, DragoGT collects the corn while the auger conveys and groups corn residues into a strip (swath).

The swath is formed without the residue touching the ground, thus remaining clean.

The material can then be easily collected by a self-loading wagon or a forage harvester-loader.

The biomass harvested will be used to create biomethane. The residues go back to fertilise the field.

An exclusive system that contributes to a sustainable development and creates added value to the agricultural income.

– Sunflower kit

Lateral and rear fall protection grid

Sunflower stalk cutting rotor

– Ear stopping rubber elements

Ideal for hill areas or difference in height

– Stalk pressing kit

For combine-harvester tyre protection

– Auto-pilot

– Sensors kit

Automatic levelling sensors kit

– Light bar

For on-road transport

Via Cuneo, 41

12040 Margarita

(Cuneo) Italy

tel +39.0171.384898

fax +39.0171.384904

www.olimac.it

infodrago@olimac.it